Nuclear will play an important role in the UK achieving a clean power system by 2030 and beyond with life extensions for the current fleet and a new generation of nuclear plants, according to independent energy system planner and operator, the National Energy System Operator (NESO). ;

Nuclear will play an important role in the UK achieving a clean power system by 2030 and beyond with life extensions for the current fleet and a new generation of nuclear plants, according to independent energy system planner and operator, the National Energy System Operator (NESO).

NESO has released a comprehensive and independent analysis of how to achieve Clean Power in 2030. This advice was commissioned in August by the Secretary of State for Energy Security and Net Zero, Ed Miliband.

The analysis shows that overall systems costs should not increase for a clean power system. Other factors could reduce electricity bills in 2030, including a reduction in legacy policy costs (as contracts expire) and energy efficiency improvements. Government policy decisions could also reduce bills by 2030.

"Our clean power pathways see Great Britain become a net exporter of power and reduce the share of unabated gas generation to below 5%," the report says. "All our pathways involve early electrification of heat, transport and industry. A reductionist approach that slows down electrification to lessen the challenge of clean power would undermine the core objectives of cutting energy costs and supporting net-zero.

"Our clean power pathways see a four-to-fivefold increase in demand flexibility (excluding storage heaters), an increase in grid connected battery storage from 5 GW to over 22 GW, more pumped storage and major expansions in onshore wind (from 14 GW to 27 GW) and solar (from 15 GW to 47 GW) along with nuclear plant life extensions."

NESO says nuclear power will play an important role in achieving a clean power system by 2030 and beyond into the 2030s, when a new generation of nuclear plants can help replace retiring capacity and meet growing demand as the economy electrifies.

Most of the UK's existing reactors are due to retire before 2030 and these are currently being considered for life extension. A new plant is also under construction at Hinkley Point C.

"In combination, we assume these see a reduction in Great Britain's nuclear capacity from 6.1 GW in 2023 to 3.5-4.1 GW in 2030, with scope for more new build beyond 2030," NESO said. "Our baseline assumption includes Sizewell B, one unit at Hinkley Point C and a lifetime extension of one AGR unit."

It notes that small modular reactors (SMRs) could be constructed and put into operation by 2030. "Should that be possible, it could compensate for any shortfall should plant life extensions not proceed as we have assumed and/or if Hinkley Point C does not begin generation until after 2030.

"If SMRs can be built in addition to our other assumptions, that could compensate for under-delivery elsewhere in the clean power programme. Beyond 2030, it is clear that SMRs and/or other large nuclear projects provide solid base generation that delivers a large contribution to clean power. There is also the opportunity for these plants to provide heat."

NESO says that delivering Clean Power by 2030 requires "swift action from industry, regulators, government, and NESO, necessitating significant changes in approach. The right supply, demand, networks and flexibility all need to be developed. A key challenge will be making sure all deliver simultaneously, in full and at maximum pace, in a sustainable way to set Great Britain on the right path beyond 2030".

"There's no doubt that the challenges ahead on the journey to delivering clean power are great," said NESO CEO Fintan Slye. "However, if the scale of those challenges is matched with the bold, sustained actions that are outlined in this report, the benefits delivered could be even greater.

"A clean power system for Great Britian will deliver a backbone of home-grown energy that breaks the link between volatile international gas prices; that is secure and affordably powers our homes and buildings; that decarbonises the transport that we take to school and work; that drives the businesses of today and catalyses the innovations of the future."

Government will now consider the advice in developing its clean power action plan later this year.

Tom Greatrex, chief executive of the Nuclear Industry Association, welcomed NESO's recognition of nuclear's role in helping the UK achieve a clean energy system.

"Ramping up baseload nuclear – including delivering Sizewell C, a fleet of small modular reactors and a new project at Wylfa – is particularly important during the still, cloudy periods like we're seeing this week when there's no other option than to burn lots of dirty, expensive gas," he said.

"For the system operator to be able to do their job there needs to be enough firm, clean power on the grid, both to keep the lights on and to protect consumers from paying inflated prices for the electricity they rely on."

The core catcher for unit 4 at Egypt's El Dabaa nuclear power plant is expected to be installed by the end of the year. It means all four units will have passed that landmark within little more than a year. ;

The core catcher for unit 4 at Egypt's El Dabaa nuclear power plant is expected to be installed by the end of the year. It means all four units will have passed that landmark within little more than a year.

The 6.1-metre diameter core catcher (also known as a melt trap) is a key bit of safety equipment for the VVER-1200 reactor - it is a container in the form of a cone made of thermally resistant steel which in the unlikely event of an emergency will securely hold the melt of the core and not allow radioactive substances to leave the containment of the reactor.

Manufacturing of the core catcher took about 14 months, after which it set sail from the Russian port of Novorossiysk on 28 October and was delivered on 4 November (see picture above). Egypt's Nuclear Power Plants Authority (NPPA) said that installation by Atomstroyexport, part of Rosatom, would begin on 19 November, the ninth anniversary of the signing of the Egypt-Russia intergovernmental agreement on cooperation on building and operating the plant.

The core catcher for unit 4 had been scheduled for installation in 2025, but the project is currently running ahead of schedule. NPPA called it "another major milestone" for the country's first nuclear power plant project.

Alexey Kononenko, director of the El Dabaa NPP construction project, said that the core catchers for the first two units were installed in 2023 and the aim is to have installed the two for units 3 and 4 in 2024. He added: "We are successfully working on the simultaneous construction of all four power units of the first Egyptian NPP, using advanced technologies and modern engineering solutions ... we have moved from individual unique projects to an industrial flow method of construction."

The El Dabaa nuclear power plant project - about 320 kilometres north-west of Cairo - is based on contracts that entered into force on 11 December 2017. The plant will comprise four VVER-1200 units, like those already in operation at the Leningrad and Novovoronezh nuclear power plants in Russia, and the Ostrovets plant in Belarus.

The contracts stipulate that Rosatom will not only build the plant, but will also supply Russian nuclear fuel for its entire life cycle. They will also assist Egyptian partners in training personnel and plant maintenance for the first 10 years of its operation. Rosatom is also contracted to build a special storage facility and supply containers for storing used nuclear fuel.

The largest and heaviest module - the CA20 - has been installed at unit 2 of the Xudabao nuclear power plant in China's Liaoning province, China National Nuclear Corporation subsidiary China Nuclear Power Engineering Company Limited has announced. ;

The largest and heaviest module - the CA20 - has been installed at unit 2 of the Xudabao nuclear power plant in China's Liaoning province, China National Nuclear Corporation subsidiary China Nuclear Power Engineering Company Limited has announced.

The CA20 module - 20.7 metres long, 14.2 metres wide and 21 metres high and weighing just over 1000 tonnes - was hoisted into place on 3 November, the company said.

The cuboid-shaped steel module will comprise of plant and equipment for used fuel storage, transmission, the heat exchanger and waste collection, among other things.

"This is another large structural module of unit 2 after the bottom head was hoisted into place on 27 October 2024, laying a solid foundation for the structural construction of the auxiliary plant of the nuclear island," CNPEC said.

The construction of units 1 and 2 of the Xudabao (also known as Xudapu) plant was approved by China's State Council on 31 July last year.

On 6 November last year, the Ministry of Ecology and Environment announced that the National Nuclear Safety Administration had decided to issue a construction licence for Xudabao units 1 and 2, which will both feature 1250 MWe CAP1000 reactors - the Chinese version of the Westinghouse AP1000. A ceremony was held on 15 November at the Xudabao site near Xingcheng City, Huludao, to mark the start of construction of unit 1. Construction of unit 2 began on 17 July this year.

The Xudabao project was originally expected to comprise six CAP1000 reactors, with units 1 and 2 in the first phase. However, with a change in plans, construction of two Russian-supplied VVER-1200 reactors as Xudabao units 3 and 4 began in July 2021 and May 2022, respectively. These units are expected to be commissioned in 2027 and 2028.

The Xudabao plant is owned by Liaoning Nuclear Power Company Ltd, in which CNNC holds a 70% stake with Datang International Power Generation Company holding 20% and State Development and Investment Corporation owning 10%.

Work to dismantle the systems and components inside the reactor building has begun at Italy's shut down Caorso nuclear power plant, Società Gestione Impianti Nucleari SpA announced. ;

Work to dismantle the systems and components inside the reactor building has begun at Italy's shut down Caorso nuclear power plant, Società Gestione Impianti Nucleari SpA announced.

Caorso - an 860 MWe boiling water reactor - was closed in 1990 after just 12 years of operation and is now being decommissioned. The plant's decommissioning licence was obtained in 2014.

Società Gestione Impianti Nucleari SpA (Sogin) said workers have already begun tracing the cutting points to dismantle the systems and components into pieces. This work is necessary, it said, to ensure that each element can be easily identified and grouped based on the plant system it comes from and its possible contamination.

The activities carried out so far have included the creation of the construction site electrical system and will continue with the installation of the vehicles for handling the dismantled materials and the setting up of a plant for hot cutting, specifically designed to tackle the most complex components in terms of size and thickness.

The first systems and components to be dismantled will be those located at ground level, Sogin said. This will free up space for the passage of materials from other floors of the reactor building. At ground level there is a confined corridor, called the waste route, created by Sogin, where the cut components will be transferred to the turbine building to be decontaminated, cut and further reduced in volume to facilitate their subsequent management.

The dismantling project is divided into various areas, each of which includes a detailed dismantling plan. This planning ensures compliance with the safety criteria and requirements indicated by the National Inspectorate for Nuclear Safety and Radiation Protection.

A total of 3400 tonnes of material will be dismantled, of which about 88% will be releasable after the necessary treatment and decontamination operations, while the remaining 12% will be managed as radioactive waste and stored on-site pending transfer to the national repository, once available.

Plant's owners hope analysis of tiny sample will help to establish how to safely decommission facility.

A remote-controlled robot has retrieved a tiny piece of melted radioactive fuel debris it collected from inside one of three damaged reactors at the Fukushima-Daiichi nuclear power station in Japan.

Tokyo Electric Power Company (Tepco), which manages the facility north of Tokyo, said the extendable fishing rod-like robot successfully clipped a piece of gravel of about 5mm from the top surface of a mound of molten fuel debris that sits at the bottom of the Unit 2 reactor’s primary containment vessel.

The “telesco” robot returned to an enclosed container for safe storage after workers in full hazmat gear pulled it out of the containment vessel.

An earlier operation to remove a small amount of fuel debris from Unit 2 was cancelled because of technical issues.

Tepco was aiming to retrieve just three grams of fuel debris as part of a demonstration programme for the unprecedented cleanup of the station, which is expected to take decades and cost about 23 trillion yen ($161bn, €145bn).

About 880 tonnes of fuel debris remain in the three reactors that suffered meltdown following the March 2011 earthquake and tsunami, according to estimates by the International Research Institute for Nuclear Decommissioning.

Tepco said that in Units 1, 2 and 3, the fuel and the metal cladding that forms the outer jacket of the fuel rods melted, then re-solidified as fuel debris.

“Fuel debris” refers to this melted fuel and other substances after they cooled and re-solidified.

Hyundai Engineering & Construction, Westinghouse and Kozloduy NPP - New Builds have signed an engineering contract for new capacity at Bulgaria's Kozloduy nuclear power plant. ;

Hyundai Engineering & Construction, Westinghouse and Kozloduy NPP - New Builds have signed an engineering contract for new capacity at Bulgaria's Kozloduy nuclear power plant.

Bulgaria's Prime Minister, Dimitar Glavchev, speaking at the signing ceremony, said: "Bulgaria has 50 years of experience in the safe and secure operation of nuclear facilities. Today, we are building on this experience. Our work with the undisputed leaders Westinghouse and Hyundai on this project is a serious step towards the implementation of one of the government's main priorities related to the development of nuclear energy."

Energy Minister Vladimir Malinov said: "The development of nuclear energy in strict compliance with international standards for safety and environmental protection is one of the main priorities of the government. Our consistent efforts and active work together with our partners at Westinghouse and Hyundai in fulfilling this priority have led to today's result - the signing of an engineering contract for the new facilities. This is a key stage that makes the process irreversible."

He added that signing the contract meant that schedule and finance details would be firmed up within 12 months for the new capacity.

Kozloduy units 1-4 were VVER-440 models which the European Commission classified as non-upgradeable and Bulgaria agreed to close them during negotiations to join the European Union in 2007. Units 5 and 6 feature VVER-1000 reactors that were connected to the grid in 1987 and 1991, respectively. Both units have been through refurbishment and life-extension programmes to enable extension of operation from 30 to 60 years. The country's two operable reactors generate about one-third of its electricity.

The aim is for the first new Westinghouse AP1000 unit - unit 7 at Kozloduy - to be operational in 2035 and the second one - unit 8 - to be operational in 2037. The 2300 MWe capacity of the two new units would exceed the 1760 MWe capacity of the closed first four units. The Bulgarian government has also said that further units will be needed to replace units 5 and 6 by 2050.

The first of two demonstration Guohe One (CAP1400) reactors at Huaneng Group's Shidaowan site in China's Shandong province has been connected to the grid. The 1400 MWe pressurised water reactor design is intended to be deployed in large numbers across the country, as well as for export. ;

The first of two demonstration Guohe One (CAP1400) reactors at Huaneng Group's Shidaowan site in China's Shandong province has been connected to the grid. The 1400 MWe pressurised water reactor design is intended to be deployed in large numbers across the country, as well as for export.

The CAP1400 is an enlarged version of the CAP1000 PWR developed from the Westinghouse AP1000, with consulting input from the USA-based company.

Research and development for Guohe One began in 2008. In December 2009, the State Nuclear Plant Demonstration Company – a 55-45% joint venture company by State Power Investment Corp (SPIC) and China Huaneng Group – was set up to build and operate two demonstration unit of the CAP1400 at Huaneng's Shidaowan site at Rongcheng. SPIC officially launched the CAP1400 reactor design in September 2020.

Construction of unit 1 started in June 2019 and unit 2 in April 2020. The reactor design is expected to take 56 months to build, with later units coming down to 50 months.

The National Nuclear Safety Administration issued an operating license for the first Guohe One demonstration reactor in late July this year.

Speaking at a press conference on 31 October, Dong Wancheng, deputy director of the Development Planning Department at the National Energy Administration (NEA), announced that the first CAP1400 unit at Shidaowan had been successfully connected to the grid.

The reactor will now undergo gradual power ascension testing and trial operation verification before officially entering commercial operation.

"After it is put into operation, the annual power generation will be 11.4 billion kilowatt-hours, which can meet the electricity needs of more than 11 million residents and reduce greenhouse gas emissions by more than 9 million tonnes per year," NEA noted.

It added: "Since 2022, several CAP series third-generation nuclear power units under the State Power Investment Corporation have been approved to start construction, and this series of nuclear power models will usher in a peak period of construction in the next few years."

In May 2016, the CAP1400 design successfully passed the International Atomic Energy Agency's Generic Reactor Safety Review. This review is not a clearance process but a review of the quality of the safety documents identifying strengths, weaknesses and gaps. International use of the CAP1400 is still dependent on meeting country-specific standards and requirements, but passing the IAEA safety review will make this process easier.

Hualong One unit scheduled for commercial operation in 2025

China has completed pouring concrete over the outer dome of the containment building for the Zhangzhou-2 nuclear power plant under construction in Fujian province, southeastern China.

According to the China Nuclear Energy Association (CNEA), the move marked the completion of the main structure and paves the way for cold functional testing at the plant.

Zhangzhou-2 is a domestic 1,126-MW HPR1000, or Hualong One, pressurised water reactor (PWR).

Construction began in September 2020 and the unit is scheduled for commercial operation in 2025, according to earlier reports.

There are three other Hualong One PWRs under construction and commissioning at the site. Last month, China National Nuclear Corporation (CNNC) said it started fuel loading at Zhangzhou-1.

Construction of Zhangzhou-3 and -4 began in Feb 2024 and Sep 2024.

The Hualong One is an indigenous, three-loop pressurised water reactor. It incorporates elements of CNNC’s ACP1000 and China General Nuclear’s ACPR1000+ reactor designs.

It is Beijing’s domestic flagship reactor technology, with 17 of the 28 reactor units under construction in China being of the Hualong One design. There are also two Hualong One plants in operation outside China, both in Pakistan at the Kanupp nuclear station, also known as Karachi.

Susquehanna owner Talen says Ferc erred and ‘we are evaluating our options’

The US energy regulator’s rejection of a special deal that would have allowed an Amazon Web Services (AWS) data centre to use more power from a nuclear power station will have a chilling effect on economic development in states such as Pennsylvania, Ohio, and New Jersey, the station’s operator has said.

Federal Energy Regulatory Commission (Ferc) commissioners voted 2-1 against a proposal that would have increased the amount of power supplied to an Amazon data centre next to the Susquehanna nuclear facility owned by Talen Energy.

The commissioners said the plan, which was an amendment filed by the regional grid operator on behalf of the parties, did not adequately prove why the special contract should be allowed under federal rules.

The plan would set a precedent and the issues should be reviewed more closely, they said.

Ferc chairman Willie Phillips dissented, saying that the grid operator addressed reliability issues and called the order “a step backward” for both electricity reliability and national security.

Talen believes Ferc erred and “we are evaluating our options” with a focus on commercial solutions. “We believe this ISA [interconnection service agreement] amendment is just and reasonable and in the best interest of consumers.”

In March, AWS paid Talen $650m (€596m) for a 960-MW data centre campus next to the Susquehanna station in Pennsylvania, and signed a long-term agreement to buy power from the plant.

The data center, Cumulus Data Assets, sits on a 1,200-acre (485 hectares) campus in Pennsylvania and is directly powered by the adjacent Susquehanna Steam Electric Station, which generates 2.5 gigawatts of power.

Talen Energy subsidiary Cumulus Data completed construction on the first building at the nuclear-powered data centre campus in January 2023.

In June, PJM Interconnection, which operates the eastern US grid, serving more than 65 million people, sought approval from Ferc to increase the amount of power used onsite to from 300 MW to 480 MW.

Utility owners American Electric Power and Exelon filed a complaint opposing the move, arguing that it could threaten grid reliability and raise customer rates.

Talen said its co-location arrangement with Amazon would bring service to the customer quickly and without expensive transmission upgrades necessary to serve large-load demand.

“But our direct-connect configuration is just one of several commercial solutions to the demand of large loads, and we are exploring other solutions as we move forward,” a statement said.

It said: “The data centre economy will require an all-of-the-above approach to satisfy the increased demand, including co-location such as Talen’s arrangement with AWS, hybrids that co-locate primary power behind the meter while using grid power for back-up, and front-of-the-meter connections to utility transmission. Talen looks forward to the continued dialogue.”

The federal order came on the heels of a day-long Ferc technical conference on the topic, which discussed the merits and challenges of co-locating data centres with existing power plants, also dubbed “behind-the-meter” demand.

AtkinsRéalis company Candu Energy Inc has announced it is entering into a special project with Canadian nuclear regulators to plan for a Pre-Licensing Design Review of the new Candu Monark reactor's suitability to be licensed and built in Canada. ;

AtkinsRéalis company Candu Energy Inc has announced it is entering into a special project with Canadian nuclear regulators to plan for a Pre-Licensing Design Review of the new Candu Monark reactor's suitability to be licensed and built in Canada.

The 1000 MW Candu Monark, a Generation III+ reactor with the highest output of any Candu technology, was unveiled in November 2023. The conceptual design phase of the reactor was completed in September, and AtkinsRéalis plans to complete the preliminary engineering by 2027.

"Reactor development is a key differentiator for us as we have the exclusive licence to deploy one of only a few large reactor technologies available worldwide, and so we have extensive experience navigating the nuclear licensing process in Canada," said Joe St Julian, AtkinsRéalis President, Nuclear. "As the world enters a nuclear market super-cycle with estimated demand for 1,000 new reactor builds, we remain on track to complete the Candu Monark's design by 2027, positioning the first Candu Monark new build to begin as early as 2029 and be completed by the mid-2030s."

The special project will familiarise Canadian Nuclear Safety Commission (CNSC) staff with the design and allow them to provide feedback on what will be needed in a future pre-licensing design review.

The CNSC's optional vendor design review (VDR) process enables CNSC staff to provide feedback to a vendor early on in the design process. Such a review aims to verify, at a high level, that Canadian nuclear regulatory requirements and expectations, as well as Canadian codes and standards, will be met as well as helping identify, and potentially resolve, any fundamental barriers to licensing for a new design in Canada. AtkinsRéalis said it believes completion of a VDR was an added measure that offers predictability to a purchasing utility.

A typical VDR includes three phases, but since the Candu Monark's design heavily leverages the platform of past Candu reactor models which have fully completed all three phases of the regulator's VDR, as well as those that have already been licensed and built, the company said it has asked the CNSC to consider two possible types of pre-licensing design review: either a VDR, or a preliminary regulatory design assessment.

The special project between the CNSC and AtkinsRéalis will see the regulator's experts develop a schedule and estimate for both a VDR and a preliminary regulatory design assessment, reflecting the impact of the range of improvements and modernisations made to Candu Monark technology, their variance to past Candu designs that have already gone through all three VDR phases, and any relevant changes to regulatory requirements and expectations.

"AtkinsRéalis will then be able to evaluate which of these pathways will be most suitable in supporting the Candu Monark design programme, with the goal of seeking rigorous review and feedback on the Candu Monark's design in support of ensuring that any eventual Candu Monark new build project can be undertaken with confidence in the licensing costs and timeline," the company said.

Leadership of the UK's STEP (Spherical Tokamak for Energy Production) programme has transitioned to UK Industrial Fusion Solutions Ltd, a wholly-owned subsidiary of the UK Atomic Energy Authority. ;

Leadership of the UK's STEP (Spherical Tokamak for Energy Production) programme has transitioned to UK Industrial Fusion Solutions Ltd, a wholly-owned subsidiary of the UK Atomic Energy Authority.

The establishment of UK Industrial Fusion Solutions Ltd (UKIFS) as a new delivery body for the UK's fusion programme was announced in February 2023 by then Science Minister George Freeman.

UKIFS will lead a public-private partnership that will design, build and operate the STEP prototype fusion plant at the West Burton power plant site in Nottinghamshire, England. The West Burton site was selected to host STEP in October 2022.

The UK Atomic Energy Authority (UKAEA) - which carries out fusion energy research on behalf of the government - said it will continue to be STEP's fusion partner, working alongside two industry partners – one in engineering and one in construction – to spearhead the development of a UK-led fusion industry.

"A major procurement exercise is currently under way to select STEP's strategic, long-term industry partners, with the shortlist expected to be announced by the end of the year," the UKAEA said.

"The launch of UK Industrial Fusion Solutions demonstrates significant progress and commitment to developing fusion as a viable clean energy source, and also to creating a UK-led fusion industry," said Paul Methven, CEO of UKIFS and Senior Responsible Owner for STEP. "STEP is a national endeavour with global impact, and we will continue to work closely with public and private sector partners to ensure the UK remains at the forefront of a revolutionary sustainable new energy source that will drive economic growth."

Ian Chapman, CEO of UKAEA, said: "UKIFS brings together an experienced team dedicated to translating decades of fusion research into a functioning prototype plant that will be capable of supplying low-carbon, safe, and sustainable energy to the grid. UKIFS will integrate partners in a national endeavour to build STEP as well as focussing on delivering enormous social and economic benefits to the UK, especially for the East Midlands region where the plant will be built."

The aim for the first phase of work on STEP is to produce a 'concept design' by the end of this year. The UK government is providing GBP220 million (USD285 million) of funding for this part. The next phase of work will include detailed engineering design, while all relevant permissions and consents to build the prototype are sought. The final phase is construction, with operations targeted to begin around 2040. The aim is to have a fully evolved design and approval to build by 2032, enabling construction to begin. The demonstration plant is due to begin operating by 2040.

The technical objectives of STEP are: to deliver predictable net electricity greater than 100 MW; to innovate to exploit fusion energy beyond electricity production; to ensure tritium self-sufficiency; to qualify materials and components under appropriate fusion conditions; and to develop a viable path to affordable lifecycle costs.

US-based company Amentum has been awarded a contract worth an estimated EUR5.5 million (about USD6 million) to consult for the first-of-a-kind dismantling of steam drum separators at units 1 and 2 of the Ignalina nuclear power plant in Lithuania. ;

US-based company Amentum has been awarded a contract worth an estimated EUR5.5 million (about USD6 million) to consult for the first-of-a-kind dismantling of steam drum separators at units 1 and 2 of the Ignalina nuclear power plant in Lithuania.

The seven-year contract with Ignalina Nuclear Power Plant (INPP) will be implemented under International Federation of Consulting Engineers (FIDIC) Yellow Book Conditions, administered by the European Bank for Reconstruction and Development (EBRD) and funded by European Commission grants.

Lithuania assumed ownership of the two RBMK-1500 units - light-water, graphite-moderated reactors, similar to those at Chernobyl - in 1991, after the collapse of the Soviet Union. It agreed to shut down the Ignalina plant as a condition of its accession to the European Union, with unit 1 shutting down in December 2004 and unit 2 in December 2009. The reactors are expected to be fully decommissioned by 2038, with most of the cost of the decommissioning being funded by the European Union via the EBRD and other funds.

Amentum said it will provide consultancy services to support INPP's Project Management Unit and carry out the duties of FIDIC Engineer for the dismantling contract. It will help INPP to manage the removal of the steam drum separators, which are large drums installed over the graphite core to divert steam to the turbines. The Project Management Unit will oversee the design and safety justification for dismantling and fragmentation of the drums and associated equipment. These are located in the plant’s radiologically contaminated primary circuit.

"We will deploy our extensive nuclear decommissioning and waste management experience from the UK, France, Czechia and Slovakia to this ground-breaking project,” said Andy White, who leads Amentum Energy & Environment International.

Amentum was created in early 2020 from the spin-off of US-based global infrastructure firm AECOM's Management Services business. Through its heritage firms, Amentum has been working at Ignalina for more than 20 years on projects including the delivery of the New Interim Spent Fuel Storage Facility and other facilities required for decommissioning.

In September, Amentum completed a merger with Jacobs Solutions Inc's Critical Mission Solutions and Cyber and Intelligence government services businesses to form an independent, publicly traded company called Amentum Holdings, Inc. The combination was described by Amentum CEO John Heller as transformational for the company, forming a "global leader in advanced engineering and innovative technology solutions".

The International Atomic Energy Agency has reported that "a small water leakage was detected from an impulse line - essentially a small pipe - connected to" Zaporizhzhia nuclear power plant's first unit’s primary circuit, with repairs taking place and no "immediate...

The International Atomic Energy Agency has reported that "a small water leakage was detected from an impulse line - essentially a small pipe - connected to" Zaporizhzhia nuclear power plant's first unit’s primary circuit, with repairs taking place and no "immediate issue for nuclear safety".

According to the update from the IAEA, the repairs required the pressure in the primary circuit to be decreased to atmospheric levels and the operators of the plant - which has been under Russian military control since March 2022 - told them on Thursday the welding work had been completed and radiography checks of the welds were on-going.

Director General Rafael Mariano Grossi said: "The agency will continue to follow this issue closely, although we don’t see any immediate issue for nuclear safety. In general, we have identified regular equipment maintenance - which is vital to ensure sustainable nuclear safety and security - as a challenging area for the Zaporizhzhia nuclear power plant during the conflict."

All six of Zaporizhzhia's units have been in cold shutdown and, following this shutdown for maintenance, unit 1 is expected by the IAEA to be put back into cold shutdown.

The operators of the plant said on Telegram that a "microcrack in the pipeline was discovered and promptly eliminated", and after testing has confirmed the successful repair "it will be put into operation". The update added that radiation levels at the plant and surrounding area was unchanged.

The IAEA has had experts stationed at the Zaporizhzhia plant for more than two years, seeking to protect nuclear safety and security at the site, which is close to the frontline of the Ukrainian and Russian forces. The IAEA says the current team at the plant "continue to hear explosions daily, although no damage to the plant was reported".

There are also IAEA teams at Ukraine's three other operating nuclear power plants, with those at Khmelmnitsky reporting that drones had flown within 400 metres of the plant. Grossi said: "Frequent reports of drones flying near nuclear power plants continue to be a source of deep concern for nuclear safety and security. As we have stated repeatedly, any military activity in the vicinity of nuclear power plants represents a potential risk."

Nigerien government has pledged support for plans, but other miners have faced major setbacks

Global Atomic said it anticipates securing a project financing loan from a US development bank by early in the first quarter of 2025 to advance its Dasa uranium project in Niger.

The Canada-based company reported that in recent discussions, the bank confirmed its intention to approve a $295m (€271m) debt facility, which would cover 60% of the project’s projected costs.

Dasa is the highest-grade uranium deposit in Africa, surpassed only by grades found in Canada’s Athabasca Basin, and is scheduled to achieve commercial production in early 2026.

“The approval timelines outlined by the bank support yellowcake deliveries in 2026 as anticipated in the four offtake agreements we have in place with American and European nuclear power utilities,” said Global Atomic president and chief executive officer Stephen Roman.

“To help fund the continuing development of Dasa until the bank funds are available, earlier this month we raised CAD40 million [€26m, $29m] in an oversubscribed public offering.”

In addition to the unnamed development bank, Global Atomic is in discussions with parties regarding potential joint venture investment in the Dasa Project and other financing solutions, the company said.

According to Global Atomic, earthworks and civil engineering are progressing in preparation for the installation of plant equipment, components of which are now arriving at the site.

In August it emerged that the US development bank postponed a scheduled July presentation about the Dasa project to its credit committee, with Global Atomic saying it would move to “finalise other financing discussions” if there were further delays.

The Nigerien government has pledged its full support for the Dasa project, but other uranium developers in Niger faced major setbacks this past summer.

In June, Niger’s ruling military junta, which came to power following a coup in July 2023, revoked the operating licence of French company Orano at the Imouraren mine, which sits on one of the biggest uranium deposits in the world.

Orano said last week it would halt its uranium production in Niger from 31 October, citing a “highly deteriorated” situation and its inability to operate.

In July, Canada-based GoviEx Uranium said the junta had withdrawn its licence for the Madaouela uranium mine, dealing a major blow to the development of one of the world’s largest uranium projects.

The coup led the US to suspend government funding for Dasa. Still, the company managed to raise CAD15m in January and CAD20m in July by selling stock.

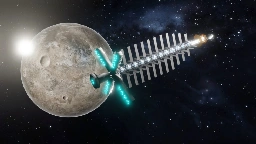

A consortium led by Belgian engineering firm Tractebel has completed the European Space Agency-commissioned RocketRoll project on nuclear electric propulsion for space exploration. The consortium has defined a comprehensive technology roadmap to equip Europe with advanced propulsion systems capable ...

A consortium led by Belgian engineering firm Tractebel has completed the European Space Agency-commissioned RocketRoll project on nuclear electric propulsion for space exploration. The consortium has defined a comprehensive technology roadmap to equip Europe with advanced propulsion systems capable of undertaking long-duration missions.

The RocketRoll project - or 'Preliminary European Reckon on Nuclear Electric Propulsion for Space Applications' - brought together leading stakeholders in aerospace and nuclear within a consortium led by Tractebel that includes the French Alternative Energies and Atomic Energy Commission (CEA), ArianeGroup, Airbus and Frazer Nash. It also included researchers from the University of Prague, the University of Stuttgart and engineers from OHB Czechspace and OHB System in Bremen.

The partners studied the feasibility of an electric nuclear propulsion (NEP) system where the electricity produced by a nuclear power reactor powers electric ion thrusters - ionising a gas and accelerating the ions produced, which are then ejected to generate thrust. This method's thrust is lower but continuous, and with far greater fuel efficiency it has higher speeds and could cut 60% off the Mars travel time of traditional chemical rockets.

"Thanks to its huge energy density, NEP offers disruptive advantages in terms of speed, autonomy, and flexibility," Tractebel said. "This innovative propulsion technology has the potential to transform space exploration and space mobility by enabling longer-duration missions, potentially shaping the future of interplanetary exploration."

The RocketRoll project, which started more than a year ago and concluded last month, has now submitted a technology roadmap to develop an NEP system, including a candidate design for a demonstrator spacecraft that could flight test NEP systems for deep space missions by 2035.

"I am proud to lead such an important initiative in nuclear electric propulsion, which could enable exploration and in-space logistics in Earth Orbit and beyond on a scale that neither chemical nor electrical propulsion could ever achieve," said Brieuc Spindler, Space Product Owner, Tractebel. "I am committed to navigating the intricate technical and strategic challenges ahead. By leveraging its nuclear expertise and innovative solutions, Tractebel helps advance space technologies and push the boundaries of the final frontier's exploration."

Currently, European space missions depend on external sources for nuclear capabilities. Tractebel says its strategy is to engineer a range of nuclear power solutions, from radioisotope to fission systems, while also contributing to developing a European value chain for nuclear solutions in space applications.

According to the European Space Agency: "NEP would enable exploration and in-space logistics in Earth Orbit and beyond on a scale that neither chemical nor electrical propulsion could ever provide. The ultimate raison d'être of NEP is to explore beyond Mars orbit where solar power is limited.

"In addition, NEP could have strong synergies with other space application. For instance, nuclear power could be used on the Moon or Mars surface to power future habitats or robotic exploration of the solar system, or in space for other purpose than propulsion."

A new strategic partnership between Kazakhstan and Mongolia's national atomic companies will provide new opportunities for the uranium industries of both countries, Kazatomprom's CEO has said. ;

A new strategic partnership between Kazakhstan and Mongolia's national atomic companies will provide new opportunities for the uranium industries of both countries, Kazatomprom's CEO has said.

The agreement to establish a partnership with MonAtom LLC was a "significant" result of the recent visit by President Kassym-Jomart Tokayev of Kazakshtan's recent official visit to Mongolia, Kazatomprom CEO Meirzhan Yussupov said. "The opportunities for implementing joint projects will allow us to combine resources and exchange experience and technologies, which will increase the efficiency and safety of uranium exploration and production," he said. "We strive for environmentally-friendly and safe development of the industry and are confident that this partnership will help to strengthen the positions of Kazakhstan and Mongolia in the international arena.

The new cooperation creates prospects for implementing joint projects in uranium exploration and mining in Mongolia, allowing both parties to strengthen their positions in the uranium industry, Kazatomprom said. "The companies plan to expand cooperation in the future and to consider a possibility of implementing joint initiatives aimed at strengthening the positions of Kazatomprom and MonAtom in the international uranium market," it added.

The agreement between Kazatomprom and MonAtom was reached during the state visit to Mongolia by President Tokayev, which also saw the signature of a Memorandum of Cooperation in the field of nuclear energy between Kazakhstan's Ministry of Energy and Mongolia's Atomic Energy Commission.

Tokayev and Mongolia's President Ukhnaa Khurelsukh welcomed the signing of the Memorandum of Cooperation in a joint declaration on strategic partnership between Mongolia and Kazakshtan issued at the conclusion of Tokayev's visit to Ulaanbaatar on 29 October.

Mongolia has substantial known uranium resources, although no uranium has been mined there since the closure in 1995 of an open-pit mine at the Dornod deposit in the north-east of the country. The Dornod mine was operated by Russian interests, and produced 535 tU during six years of production. Ore from the mine was transported by rail to the Priargunsky facility in Krasnokamensk, Russia, for processing.

French nuclear company Orano has had a presence in Mongolia since 1997, and is working to develop the Zuuvch Ovoo project - which it says has a potential 30-year mine life - through its Badrakh Energy joint venture with MonAtom.

Running my own instance, where do you change the max_pinned_statuses? All I find is a variable called PIN_LIMIT, not a value. Is this something you can change?

Holtec International said it repaired 125 damaged used fuel assemblies as part of the successful completion of its recent loading campaign of 480 used nuclear fuel assemblies into 15 HI-STORM FW dry storage casks at Angra unit 2 in Brazil. ;

Holtec International said it repaired 125 damaged used fuel assemblies as part of the successful completion of its recent loading campaign of 480 used nuclear fuel assemblies into 15 HI-STORM FW dry storage casks at Angra unit 2 in Brazil.

Holtec said its team would return in early 2025 to load 75 damaged fuel containers from the Angra 1 site into 18 HI-STORM FW systems, also at the Complementary Dry Storage Unit for Spent Fuel (UAS).

Under a turnkey contract signed in 2017, Holtec of the USA supplied Eletronuclear with HI-STORM FW systems and related equipment for dry storage of used fuel from Angra units 1 and 2. Angra 1 is a Westinghouse-designed 609 MWe pressurised water reactor (PWR), while Angra 2 is a Siemens-designed 1275 MWe PWR. The units have different architectures and licensing bases, adding to the complexity of the project. Holtec modified their respective cask handling cranes and equipment for loading the fuel into the multi-purpose canisters and for moving the canisters to the dry storage facility.

PK Chaudhary, President of Holtec’s Nuclear Power Division with direct responsibility for Projects, Manufacturing & Supply Chain, said: "We thank Eletronuclear's team for their exemplary support for the Angra 2 used fuel storage campaign. We are gratified to see our innovative spent fuel storage solutions play a critical role at the Angra Nuclear Station. We look forward to a repeat success when our team returns to load used fuel at Angra 1 in early 2025."

The storage facility is designed to receive fuel elements after the cooling process in pools at the plants. They are stored in canisters made of steel and concrete to guarantee safety. It is a system which is used in the USA and is designed to withstand extreme events such as earthquakes and floods.

It includes physical security, radiation and temperature monitoring, an armoured access control centre and a storage warehouse with a technical workshop, designed and constructed by Holtec. The facility was constructed because the storage pools of both units were reaching full capacity. It is designed to hold up to 72 modules, with the capacity to receive used fuel until 2045.

Holtec said it used its Fuel Repair Device (FRD) to repair the damaged used fuel assemblies, technology which it used for the first time during refuelling at its Indian Point Nuclear plant in the USA last year. It says that its system renders a damaged fuel assembly that cannot be handled by normal means into one that can be handled in a normal manner using the plant’s existing fuel handling tooling and is "the only fuel repair technology available in the industry that involves no welding or introduction of any foreign material in the fuel pool".

Holtec says that in 2025 at Angra 1 it will load 18 HI-STORM FW systems with 75 damaged fuel containers and used fuel will be stored in MPC-37 canisters, each of which can contain 37 PWR used fuel assemblies.

The American Bureau of Shipping has released its latest report into the potential of advanced nuclear technology for maritime applications, with a study of a small modular reactor on a standard liquefied natural gas carrier. ;

The American Bureau of Shipping has released its latest report into the potential of advanced nuclear technology for maritime applications, with a study of a small modular reactor on a standard liquefied natural gas carrier.

The report notes that large liquefied natural gas (LNG) carrier vessels are increasing in demand as the international LNG trade remains important for global energy security. LNG is stored on board in large cryogenic tanks that maintain natural gas (primarily methane) in a liquid state around -165°C. The typical energy demand for LNG carriers is between 30 to 75 MW.

The scope of the American Bureau of Shipping (ABS) study - titled Pathways to a low carbon future: LNG carrier nuclear ship concept design - was to consider and discuss a standard LNG carrier design using nuclear power for propulsion and other primary energy needs. A conceptual future zero-emissions LNG carrier is presented to illustrate how one type of advanced nuclear fission technology may be applied for shipboard power in the future, with an emphasis on what aspects of ship and reactor design may require further investigation to guide the development of the integrated technology and regulatory framework.

The transformational impact of a high-temperature, gas-cooled reactor (HTGR) on the design, operation and emissions of a 145,000-cubic-metre LNG carrier design was modeled by ABS and Herbert Engineering Corporation. ABS said the study was designed to help industry "better understand the feasibility and safety implications of nuclear propulsion and to support future development projects".

The study shows a nuclear-propelled LNG carrier would have specific design features, with reactors placed at the rear of the vessel (to shield the cryogenic cargo from the thermal load of the reactor compartment) and batteries forward of the location occupied by fuel tanks on current vessels and a reinforced hull. Given design constraints, the HTGR technology would only be suitable for larger LNG carriers.

"The study provides ABS and the industry important information on heat and energy management, shielding, weight distribution, and other design features for an LNG carrier with nuclear propulsion," ABS said. "This will assist the identification of design issues that will inform future Rules development. The study also found the HTGR technology allowed faster transit speeds and offers zero-emission operations. There would also be no requirement to refuel, although the HTGR technology would need replacing approximately every six years."

ABS said the benefits from nuclear propulsion include decarbonised high-power availability, reduced or eliminated bunker costs, and associated reduced bunker time in port.

"Nuclear power would be an ideal means of drastically abating shipping emissions, but significant hurdles remain in public perception and international regulations before this can be achieved," it adds.

"While this technology is well understood on land, adapting it for marine application is in its infancy," noted ABS Senior Vice President and Chief Technology Officer Patrick Ryan. "However, this study and the other research we have carried out clearly highlight its significant potential to address not only shipping's emissions challenge but to deliver a range of other operational advantages to the industry. ABS is committed to helping the industry evaluate its suitability for use in a range of use cases and LNG carriers is just one of a range of potential applications we are exploring."

In August 2022, ABS announced it had been awarded a contract by the US Department of Energy (DOE) to research barriers to the adoption of advanced nuclear propulsion on commercial vessels. Working with support from DOE's National Reactor Innovation Center, based at Idaho National Laboratory, ABS is developing models of different advanced reactor technologies for maritime applications and developing an industry advisory on the commercial use of modern nuclear power.

In July last year, a study commissioned by ABS explored the potential of advanced nuclear reactor technology for commercial marine propulsion. ABS commissioned Herbert Engineering Corporation to carry out a study designed to help the shipping industry better understand the feasibility and safety implications of nuclear propulsion and to support future development projects. The study modelled the impact of nuclear propulsion on the design, operation and emissions of a container vessel and a Suezmax tanker.

The Czech Republic's competition authority has issued a preliminary ruling rejecting the appeals by Westinghouse and EDF about the tender process for new nuclear units in the country which saw Korea Hydro & Nuclear Power selected. ;

The Czech Republic's competition authority has issued a preliminary ruling rejecting the appeals by Westinghouse and EDF about the tender process for new nuclear units in the country which saw Korea Hydro & Nuclear Power selected.

In a ruling published on Thursday, the Office for the Protection of Competition (UOHS) said it had "decided in the first instance on the proposals of the companies Électricité de France and Westinghouse Electric Company LLC against the procedure of the contracting authority Elektrárna Dukovany II in the tender for the construction of a new nuclear power plant. The proceedings on the proposals of both companies were mostly terminated, while other parts of the proposals were rejected. The decisions are not final and the parties to the proceedings may lodge an appeal with the Chairman of the Office".

It said that Westinghouse's objection "against the procedure of the contracting authority outside the framework of the Public Procurement Act on the basis of the so-called security exception" did not proceed "because the company should have filed its objections to the use of the exemption no later than 15 days after it became aware of the use of this procedure, which was in March 2022. However, the objections were not received by the contracting authority until 1 August 2024".

It also says that "both applicants also argued that the contracting authority had acted illegally in failing to comply with the basic principles of public procurement ... for example, the substantial extension of the subject of performance of the public contract in question, the inability of the preferred supplier to perform the contract, etc". However this complaint was also not taken forward "because no legal objections can be raised against the specific procedure of the contracting authority in awarding the public contract outside the procurement procedure using the exception under Article 29(a) of the Public Procurement Act".

Both companies claimed that foreign subsidy regulations had been infringed, with EDF also alleging "a breach of the 3E principles as well", which refers to the benchmarking process for tenders. But the office "rejected the proposals in these parts because they were not directed against a procedure which the contracting authority is required to follow under the Public Procurement Act".

Because these are not final rulings the competition office added that "the prohibition to conclude a contract for the tender in question remains in effect until the decision in the case comes into force".

The ruling was published the day after it emerged that there was a ban on signing the contract pending a decision on the case. Speaking on Wednesday, Deputy Prime Minister Vlastimil Válek said that was "the standard procedure of the Office" and happens in many hundreds of cases a year "so it's nothing out of the ordinary - it's part of our legislation and I don't think it should jeopardise any of that timetable in any way".

ČEZ Group also issued a statement saying that its project company for the two new units, had "proceeded from the very beginning in accordance with the applicable laws" and it was "conducting negotiations with the preferred supplier, which is the Korean company KHNP, regarding the form of the final contract. According to the current schedule, it should be ready for signing by 31 March 2025. It can be expected that by then the ÚOHS will be able to make a decision in the proceedings so that the signing of the contract with the preferred supplier is not delayed".

The background

The Czech Republic currently gets about one-third of its electricity from the four VVER-440 units at Dukovany, which began operating between 1985 and 1987, and the two VVER-1000 units in operation at Temelín, which came into operation in 2000 and 2002.

In October last year, Westinghouse, EDF and KHNP submitted binding bids for a fifth unit at the Dukovany nuclear power plant, and non-binding offers for up to three more units - another one at Dukovany and two at the Temelin nuclear power plant. Westinghouse was proposing its AP1000, EDF was proposing its EPR1200 reactor, KHNP was proposing its APR1000. But in February the Czech government announced it was changing the tender to be binding offers for four new units, with Westinghouse not included because it "did not meet the necessary conditions".

Prime Minister Petr Fiala explained at the time that the decision to switch to binding offers for all four units was the result of the original tender suggesting that contracting for four units, rather than having separate processes, could have a 25% benefit in terms of costs.

In July, he announced KHNP as the preferred bidder, with contract negotiations to begin with the aim of signing contracts for the initial unit by the end of March 2025 - the target for test operation of the first new unit is 2036 with commercial operation in 2038. He said the winning tender "based on the evaluation of experts, offered better conditions in most of the evaluated criteria, including the price". The KHNP bid was for a cost of around CZK200 billion (USD8.6 billion) per unit, if two units were contracted.

Correct. In this case it's just shipping the component parts. I guess @KnitWit@lemmy.world was talking about PWR reactors that power these ships, much like the NS Sevmorput.

I think they might be referring to cargo like ammonia. What if we have a Beirut incident with a ship with a nuclear reactor? Something to plan ahead for sure.

Yucca mountain is a political problem, not a technical one. But sure, if you want examples of good practice, I refer to COVRA in the Netherlands, where I had a tour a few months ago. Very interesting facility. If you want a deep geological repository, there is Onkalo in Finland. I'm not a fan of dedicated DGRs, but since it's around, we might as well use it I guess.

In my view, should you care, we're not going to put away the spent fuel at all in these DGRs, but recycle them in until we used all of the fuel. At this point there actual waste, should we no longer be able to recycle this, is around 1% of the current 'waste' in volume and consists solely of short lived isotopes remaining radioactive for around 300 years. If you want to bury that, sure, I guess.

But please, now you tell us more about how fantastic the waste management is of the arsenic mining tailings in China, which are a result of digging for rare Earths to make solar panels. I look forward to it!

That's a nice analogy! Don't mind me if I use it in the future 👍

Before we can advance the use of solar panel use, the question of waste must be answered. Humans and corporations aren’t known for their responsibility.

See the double standard? No? I guess not.

Of any industry, the civilian nuclear industry has been exemplary in dealing with their waste streams, in contrast to all other energy industries. A waste stream that's actually highly recyclable and becomes no longer dangerous (unless you eat it) after just 300 years.

Nuclear waste is not an actually existing problem, and anyone raising it is employing a delaying tactic for our society moving away from fossil fuels actually killing our planet.

Nog update hierover? Outages gebeuren niet vaak, maar we waren ruim een uur (wat ik gemerkt heb) offline. Een mastodon account met status updates zou fijn zijn 🙂

Yes, vastly better. You just learned about SL-1 or something?

Public ownership would be a great idea, but it would still incur costs in the immediate sense. Things have to be updated and maintained.

"The blasting had been planned for 5.30pm but was delayed after a 36-year-old pro-nuclear protester scaled an electricity pylon near the towers in protest at their demolition."

Andreas Fichtner is now facing a legal battle for this protest. If you want to help out, please consider a donation.

Great overview, but I have two notes:

- A mention is made of the proliferation risks due to purified plutonium. But no mention is made of the difference between weaponsgrade Pu-239 and useless Pu-240. Pu-240 has the annoying characteristic that it can 'spontaneously' fission, which of course for is highly undesirable in warheads. These are mixed up and hard to separate. This simple fact makes proliferation risks at best a theoretical scenario.

- Vitrification of the fission products is explained well, but is still accompanied with the obligatory "hundreds of thousands of years" comment. This is incorrect. After 300 years, these fission products are no longer radiotoxic.

Several countries, and I guess Italy is among them, have decommissioning regulation where the old unit first has to 'cool off' for a few decades before the building can be torn down.

So, to answer of whether it is this or that, I answer: yes.

Did not expect this to go to any other company but a Russian one tbh.

Well, he knows about this community now! 🙂

So, you're then saying that nuclear is somehow more threatening to our future than fossil energy is? Wow. Thanks for being clear where you stand I guess.

Just for the record: fossil fuels not only change our planet's climate, it also kills millions of people each year due to air pollution.